Living Our Practices Submissions: December 2022

Thank You for Joining the Conversation!

“Living Our Practices” contest explores our Cultural Pillars and Practices

In December we asked: How do you or your team support operational consistency?

A big “thank you” to everyone who submitted in December’s contest. Check out the responses!

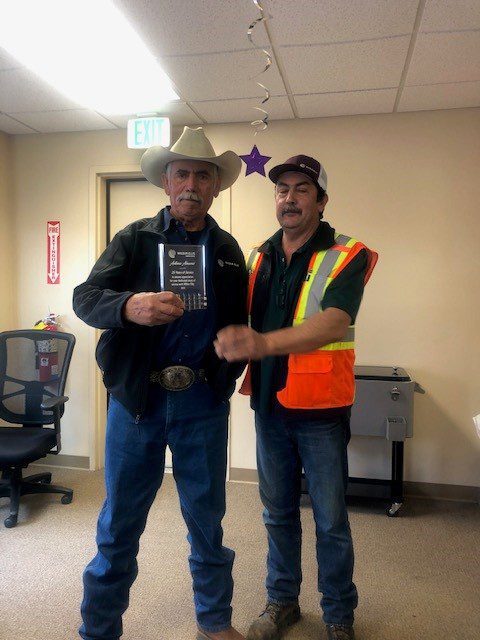

Proud Teammate (Agribusiness)

Shafter Ca, location supervisors exercise operational consistency by working alongside department employees. Warehouse manager Martin Medina is a great example of this. Not only does Martin spend most of his time with his team ensuring consistent processes, he also makes it a point to recognize high performers for operating consistently safe.

John Hoyle (Agribusiness)

Operational Consistency is paramount and truly is a separator between us and our competition I feel. The better the customer can be served, branch run efficiently, and staying safe while doing so is the difference maker for Wilbur Ellis to be successful. On the sales side of things, order consistency in Ag Verdict only helps the operations side to be consistent. It truly is a team approach to make all this happen and having the right people in place to do so.

Rebekah Will (Agribusiness)

Operational consistency is imperative to our business here in Dundee, MI. We have made it a center focus to try and improve upon our communication every year, however small the issue. It is easier to focus on the large scale issues that will immediately affect our business but can be easy to overlook the smaller ones that overtime can hurt the business. We just had our year end review with both operations and sales present. We throw everything on the table that we believe will help us in our communication/procedures to make the business run smoother from within, ultimately ensuring the customer receives an experience and product they’re pleased with. By tackling small communication issues between our team and adhering to best practices we mitigate the chance of things going wrong.

Raymundo Franco (Agribusiness)

We have daily production meetings regarding our bookings for the day/week. We communicate daily in the office about any customer inquiries or new bookings being added to fill in a timely manner. We are also in direct contact with our floor supervisors to make any needed adjustments and plan a schedule for day/night shift. Most importantly we all try to communicate as much as possible to be aware of any situation or circumstance.

Cesar Cardenas (Agribusiness)

We support operational consistency by remaining on top of in coming orders, maintenance of the warehouse such as sweeping, cleaning, restacking and consolidating pallets and products as needed.

Jonathan Nye (Nachurs)

For me it is all about consistency and processes. Consistency helps give me proper measurables on projects and timelines. Helps me as a manager to know if work loads are too much, too little, etc… and allows for me to know how I can help. Essentially if me and my team can produce consistent work, it is easier to track progress towards our end goals.

Don Sauve (Corporate)

I work with a cross-functional team to assist in Ag month end processing. We use a shared checklist to ensure that all critical processes are performed by the right person at the right time. Progress in the tasks is documented by all participants and is available for subsequent audits/reviews. If issues arise, we have a strong team with a lot of experience to work through them.

Kevin Hupp (Agribusiness)

We use Microsoft Teams to help us all stay in communication and up-to-date with our daily operations. Our operations manager has created channels within Microsoft Teams and assign members of our branch access to each channel. Some channels involve all of us (backorders) and others are specific to a select few (A/R). This is adaptively managed. We add, combine and delete channels as they get used for a while. Through Teams, any activity on the assigned channels alerts the members and they can engage or read the activity. All members are informed and up-to-date. This lessens emails and text messages that may get lost throughout a busy day. This platform has eliminated the same question asked and answered multiple times through out the day. One entry and we are all up to speed and communications are simple and precise. Our branch is so much more efficient with Microsoft Teams.

Daniel Woolley (Agribusiness)

One thing that the FP&A team for Agribusiness has done this year is created standard operating procedures for the processes that follow a set list of instructions. This has provided clear communication and helped improve efficiency in getting new team-members up and running.

Kyle Smith (Nachurs)

One of the ways I keep up with with operational consistency is by keeping in contact with my supervisors about what is going on in my territory. When I have a fertilizer or an parts/equipment issue or question I reach out to my coworkers for advice so I have the best possible solution for the grower/customer.

Sylvia Dsouza (Connell)

We can support operational consistency by setting up standard management system and continuous improvements in these system processes, by setting smart goals and focus on customer service as well as understand the importance of employees.

Guadalupe Rodriguez (Nutrition)

We hold daily meetings to communicate issues, concerns, how can we improve or correct issues or problems happening or that can happen in the next couple of days with production.

We make a schedule to ensure we understand the importance of each shipment(customer/material/equipment). Communication: who will lead the communication from the crew. Responsibility: (quality control) who will check product is in perfect condition for customer or how can we improve going forward. Most important teamwork and being focus.

Tyler Alexander (Agribusiness)

Operational consistency is a practice that I find to be crucial for a collaborative and efficient business. The way my team utilizes this practice, is within our BMO justification/approval process. To keep the language consistent throughout, we have developed a BMO justification guide to classify each transaction. This helps accelerate the justification/approval process, but most importantly, helps analyze spending dynamics for financial analytics. This will help give a more accurate representation for each spending category, while reducing time spent on BMO justifications/approvals.

Mary Fattor (-- Select an option --)

When we work together, we have to be in frequent communication and make routine updates to orders and even reach out to other departments. We kindly ask them to perform a task on their end so that the customer is able to get their order in a timely fashion. We amplify excellent customer service by familiarizing ourselves with the customers needs, adapt to the situation by having a flexible mindset while remaining calm, and activate by performing our tasks within a reasonable time frame whether that would be clarifying information by email or by phone. We keep a watchful eye on our orders and do everything we can to please our customers while following safety protocols.

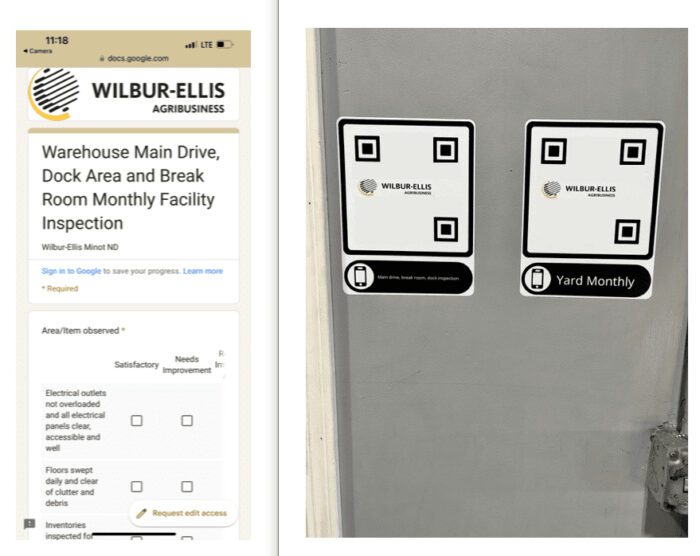

Rob Ogden (Agribusiness)

We work hard on transparency and ease of communications in Minot. One of the ways we practice Operational Consistency is with our inspections.

Sam Engel has created scannable QR’s for all of our monthly inspections. This includes everything from Eyewash Stations, Fire extinguishers, Cleaning schedules, to full Facility Inspections. Inside the QR, we have detailed inspection checklists with instructions and also diagrams/pictures when needed. This gives anyone the ability to pull, review or complete an inspection along with a scheduled reminder sent out to our team when inspections are due. I believe this helps keep our Team on track and also keep us Operationally Consistent!!

Shout out to Sam Engel, Thanks for the creativeness and ingenuity you provide to our team 🥇

Thanks to the Catalyst Team for the opportunity.

Darrin Hartsfield (Agribusiness)

I am no longer the LOM of the Hughson, CA branch, but while I was there this TEAM went 8 years (and still going) without a Time Off Incident. This team came together to build such a strong safety program that was centered around looking out for the other person. Everyone one was engaged with weekly and monthly safety committee meetings and took ownership in the safety of the branch. This was and still is an amazing team that has continued to strive to put safety first by working together even after I took another position with WECO.